Pre-cooling your cargo before loading it into the container helps insure the successful outturn at arrival.

The container's job is then to maintain that steady cargo temperature.

RF Cargo Handling

-

Cargo Pre - CoolingPre-cooling of CargoCheck product temperature during loading.(Optional) Pre-cool container to remove residual heat.

Recommended Equipment TemperatureThis brief recommended equipment temperature based on HMM's RF biz experience is

Recommended Equipment TemperatureThis brief recommended equipment temperature based on HMM's RF biz experience is

provided for your reference.RangeTemperatureExampleDeep Frozenbelow -26℃Ice creamHard Frozen-17.8℃ ~ -25℃Fish, Meat, Poultry, CrabFrozen-15℃ ~ -10℃Epoxy, MoldSensitive Chilled-3℃ ~ +5℃Chilled Meat, Fruit, VegetableMedium Chilled+6℃ ~ +15℃Silicon, Wine, ChocolateChilledOver +15℃Confectionary -

Cargo PackagingPackagingPackaging must be designed for the unique nature of your product. This will reduce the chances of damage. And, it should withstand a stacking height of up to 2.5m.Proper packaging will permit good air circulation and stable temperatures in transit.Generally, the boxes have ventilation holes on the sides. However, airflow comes from beneath in RF equipment. The good airflow would be smoothly gained if the holes are placed on top and bottom.

-

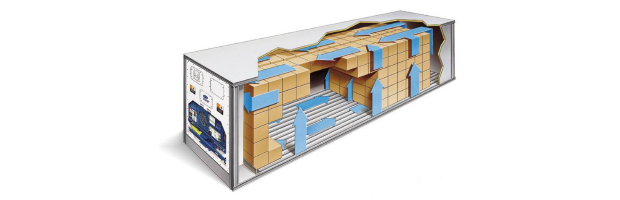

Cargo StowageStowagePoor air circulation is one of main causes of cargo deterioration. “Hot Spots” can be made by any obstruction of airflow.

Proper stowing inside the container is necessary to insure an even temperature throughout the voyage.Reefer cargoes require different stowage plans, and our reefer business specialist can advise you on this.Do not stow the cargoes in front of evaporator outlets and inlets.Leave a minimum of nine inches between the top of the load and the ceiling.

Check the redline the inside of the container.Ensure return air grill is in good condition.Turn unit off while doors are open, and minimize the time to leave the door open.There would be shake during the delivery. The cargoes should be stowed firmly to prevent shift of the packages inside the container.

Ventilation inside the ContainerDistribution of chilled air is essential to maintaining freshness of your cargo.

Ventilation inside the ContainerDistribution of chilled air is essential to maintaining freshness of your cargo.

Proper stowage allows the free-flow and circulation of air to chill all cargo evenly.